Blog

2022-05-31

2022-05-31Cassava roots is popular in African and southeast Asia. In Africa, tapioca roots can be produced to different products, such as garri, fufu, cassava flour and tapioca starch. Now, because of the strong demands of the market, tapioca starch is more popular in tapioca processing industry as in Indonesia, the tapioca is almost made into tapioca starch, and then delivered to China. If you plan to join in tapioca starch production business, you have to know how to make it. So, today HENAN JINRUI shares the processing steps to you.

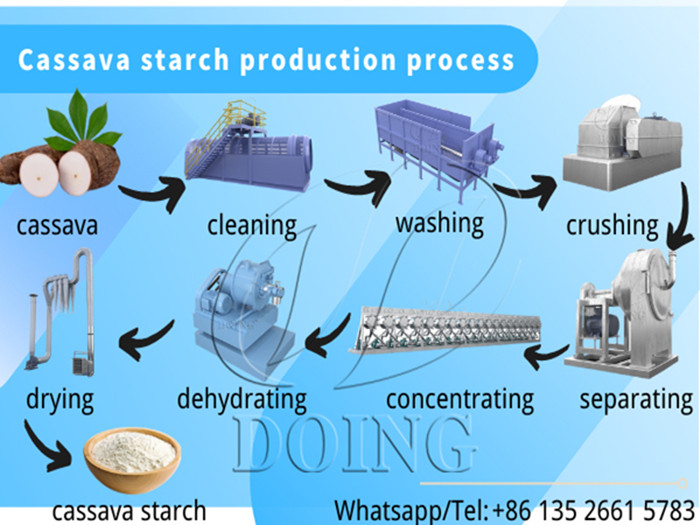

There are three main processing steps for tapioca starch production line. They are cassava roots washing and cleaning, cassava roots extraction processing and drying system. Now, please allow me to explain to you one step by one step as bellow.

Cassava starch production process

Cassava starch production process

In order to promise the factory normal running, when fresh cassava roots transported to the factory, they need to storage in factory firstly. Then feeding to the vibration hopper.

1. Cassava roots Cleaning & Washing

Firstly using dry sieve to remove sand, mud and impurities, then feeding into paddle washing machine for cleaning it.

2. Cassava roots chopping

Cassava roots is irregular and too long, then cut it firstly by chopping machine.

3. Cassava roots crushing

After chopping, feeding rasper mill to crush it. Then pump into centrifuge sieve.

4. Fiber and starch separation

Considering the starch the cleanness, fiber should be separate by centrifuge sieve, then getting crude starch.

Centrifuge sieve for cassava fiber and starch separation

Centrifuge sieve for cassava fiber and starch separation

5. Starch de-sander

After separation the fiber, remove sand by de-sander machine .

6. Starch purification

After removing sand, then purification the crude starch by hydrocyclone system.

7. Wet mash dewater

After purification, must be remove water by peeler centrifuge, the getting 36.5% or 38% moisture then feeding to flash dryer.

Cassava vacuum filter for dewatering wet mesh

Cassava vacuum filter for dewatering wet mesh

8. Drying system & packing

Feeding wet cassava mash into the flash dryer for drying, after drying the moisture is 14%, then can pack it.

The above equipment line can produce a high quality of cassava starch. If you want to set up a cassava starch production factory? Contact us now to get more details!

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).